CDES Preparation

Making Heated and Equilibrated Gases

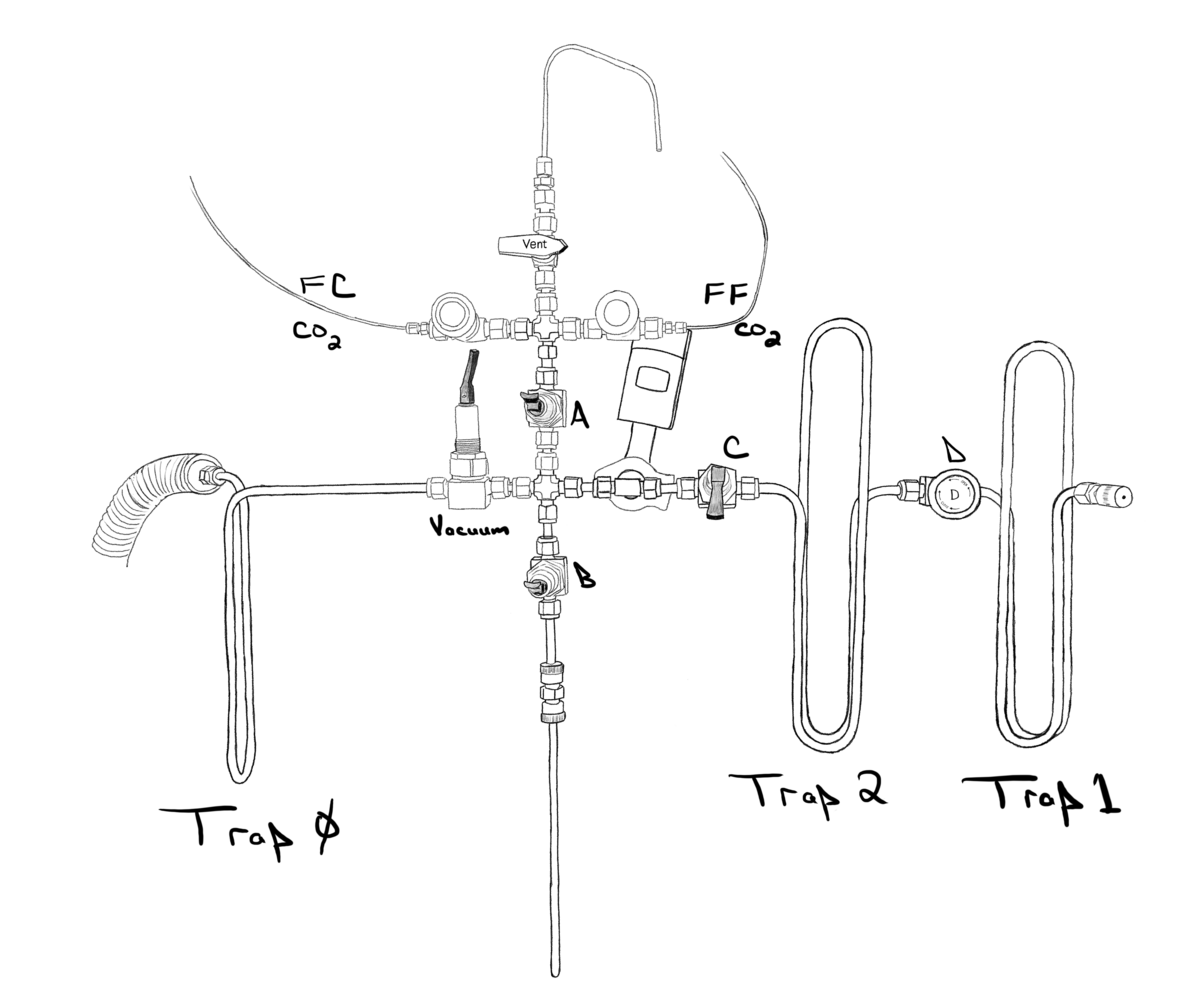

This method describes how to make equilibrated and heated gases used to create the carbon dioxide equilibrium scale (CDES) for calibration of our carbonate clumped isotope thermometer. Equilibrated gases are made by putting carbon dioxide (CO2) and water (H2O) into a vessel and allowing them to reside together at specific temperatures for an extended period of time. The types of CO2 and H2O are referred to with two letter codes. The two types of CO2 are FC (Fermented Corn) and FF (Fossil Fuel). The water types are EN (enriched), DI (deionized water from the tap), and SP (south pole). The temperatures we use are 4 °C (refrigerator), 25 °C (lab temperature), and 60 °C (drying oven). The heated gases are created by putting dry CO2 into a sealed quartz tube and heating it to 1000 °C.

- Prepare the Line:

- if a new tube is needed, do this now, close B, install new tube (Quartz for heated, pyrex for 4*C)

- have these valves CLOSED: A, Vent, FC, FF

- have these valves OPEN: Vacuum, B, C, D

- make sure line is properly pumped down

- line should pump down to near 5e-3 Torr

- prepare dewars: get liquid nitrogen, prepare slush

- freeze tip of T0 with liquid nitrogen

- with a -90 to -100 *C ethanol slush filled dewar, freeze Trap 1

- freeze trap 2 with a liquid nitrogen filled dewar

- Water-CO2 Equilibrated Gases:

- remove chosen vessel from fridge and open the green valve

- If this is the first sample of the day from either of the two refrigerated vessels, use a larger syringe to clean out the dead volume of the valve and vessel

- fill the large syringe completely, remove syringe and needle, expel syringe contents into the room

- use the 0.25 mL syringe, insert into vessel, with green button pressed in, pull the plunger back to 0.25 mL, press red in, hold needle, remove syringe.

- Heated Gases:

- make sure you have a quartz tube installed, not a pyrex tube

- [do the stuff needed to fill the syringe for making heated gases]

- Purify your CO2 of Choice:

- make note of the vacuum gauge value

- close vacuum

- pressurize the syringe (with it closed - red pushed in) to the value you wish to inject (probably very near 0.10 mL

- get ready to inject

- press green on the syringe and push through the septum

- press down the plunger

- hold the knurled part of the needle and pull the syringe out

- allow the CO2 to freeze for a bit, top off the Trap 2 liquid nitrogen dewar to ensure any frozen CO2 is submerged at liquid nitrogen temperatures

- open vacuum and pump away all of the incondensibles

- once the gauge returns to its background value (or lower), close vacuum and valve D

- remove the cold ethanol dewar from Trap 1

- in a reasonably swift motion, remove the liquid nitrogen dewar from Trap 2 and place the cold ethanol on Trap 2

- position the lab jacks under the cold ethanol dewar

- freeze the very tip of the tube with liquid nitrogen

- wait for the gauge to drop to a near-background stable value; the gauge will likely read slightly higher than the background you previously recorded

- close valve C

- remove the liquid nitrogen from the tip of the tube and warm it up with water

- write down the CO2 pressure from the gauge in the notebook; it will probably be 2.5 to 3.0 Torr

- dry the tube off if any water is present

- again freeze the very tip of the tube with liquid nitrogen

- raise the level of liquid nitrogen of T0

- when all of the CO2 is frozen and the gauge has reach some minimum value, raise the level of liquid nitrogen around the tube

- open vacuum to pump away any last incondensibles

- close vacuum and valve B

- flame seal the tube

- leave the tube in the liquid nitrogen until the tip is room temperature

- End of day cleanup

- place a new tube on the line

- have these valves CLOSED: A, Vent, FC, FF

- have these valves OPEN: Vacuum, B, C, D

- drop all dewars from their respective traps

- poor liquid nitrogen back into a parent container

- cover ethanol dewar(s) with a foam lid

- if you were making heated gases make sure the vent and the FF or FC valves are all closed

- if you were making water-CO2 gases from the refrigerator, make sure the green valves are closed

- close the torch oxygen cylinder and turn off the natural gas