Muffle Furnace

Introduction

The muffle furnace is a well insulated oven with a maximum temperature of 1100 °C. In IsoLab, it is typically used to clean glassware or otherwise remove organics from materials. The term muffle probably derives from a protective wrap one would place around their pottery before placing it in a fire pit for hardening or glazing.

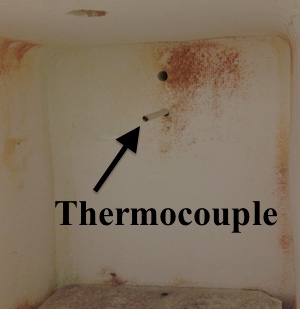

It is critical to know the location of the thermocouple (because it is fragile) and to know the melting point of whatever you are putting inside (because melting and fire are messy).

Safety

Risks associated with the muffle furnace are all related high temperatures.

Use of the muffle furnace inherently involves very high temperatures. Users should wear protective gloves and eye wear. The type of glove you choose depends on the temperature you are working with. In the drawer below the furnace, users can find glove options.

Make certain that you know the melting point of everything inside the muffle furnace. Place plastics inside the furnace is generally not a good idea as fire can result.

If you are using the muffle furnace to combust away large amounts of organic material, make sure the vent on top of the furnace is OPEN and the fume snorkel is positioned correctly. Failure to do so will result in poor air quality for everyone in the lab.

Exhaustive Protocol

Preparing Items for the Muffle Furnace

Know the melting point or flash combustion point of all items you are placing inside the muffle furnace. Cover open ends of all pyrex with aluminum foil. For smaller items, like kiel vessels, wrap them in a sheet of aluminum foil. If you are baking items at very high temperature, make certain all items inside the furnace can withstand it.

Starting the Muffle Furnace

- Place items CAREFULLY inside furnace. DO NOT disturb or bump the thermocouple in back of the furnace.

- Once the oven is filled with whatever is going to be baked, make sure the door is completely closed.

- If the oven is not already on, use the switch to turn it on.

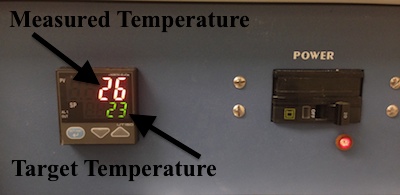

- Using the arrow buttons on the digital reader on the bottom left under the door, adjust the target temperature (the green number) to the desired temperature.

- Make sure the desired temperature is not past the melting point of any of the materials put inside the furnace.

- Press the blue button to set the temperature.

- It will take about an hour to reach the desired temperature.

- Fill out the Sign-In Sheet for the Muffle Oven.

Stopping the Muffle Furnace

- Once the furnace has been at the desired temperature for the desired amount of time, use the down arrow on the digital reader to set the temperature down to below 20 °C and press the blue button to set.

- Do not attempt to open the door until the temperature is 100 °C or below (unless you are making heated gases for clumped isotopes).

- Do not attempt to take any materials out of the oven until the digital screen is around 25°C unless you are using gloves and the temperature is under 100 °C. Cooling the oven takes longer than heating the oven up.

- Once the materials are cool, remove the items from the oven, being careful not to bump the thermocouple. Store the items in their appropriate spots.

- Close the oven door.

Suggested Temperatures and Times

- Pyrex - 500 °C - at least one hour

- Quartz - 1000 °C - at least one hour

- Fritted funnels - 480 °C - less than one hour

- Heated gases - 1025 °C - at least 2 hours

Common Melting Points

- Polypropylene - 160 °C - the flash point is 260 °C

- Aluminum - 660 °C

- Pyrex - 820 °C - this is the softening point and it depends on exact recipe

- Quartz - 1670 °C

BEWARE

- Do not put plastic in the oven.

- Keep corrosive materials away from the furnace.

- Never put explosives or highly reactive materials into the furnace.

Fire

- If you find a fire burning inside, get the fire extinguisher, located by the doors in both room 303B and 302A, put out the fire and leave the room until the air is sufficiently cleared.

- If you are unable to put out the fire, pull the alarm and get out.

Troubleshooting

- If you smell something strange coming from the muffle furnace, turn off the oven, allow it to cool to below 100 °C, and carefully open the door to determine the source. Remove contents as needed.

- If the controller displays ‘b.o’ this means ‘burn out’ and the thermocouple is probably dead. You can check the resistance after you have removed the thermocouple to see if it is an open circuit, and thus broken. Replace thermocouple as needed.