Inca Bandsaw

Introduction

This method was written after the 2017 WAIS core cutting for nitrate analysis. Prior to this, as remarkable as it may seem, no written method existed in IsoLab. John Robinson put this together to help future IsoLab ice core band saw cutters.

Cutting to clean the ice - The general goal is to remove 2-3 mm of ice from each face of a core. How exactly this is accomplished will depend on a few factors such as quantity of ice, concentration of analyte of interest, and core geometry. Below are several guidelines and thoughts for future users as well as step-by-step instructions for the DD15 style cores from WAIS divide.

Very strong recommendations:

- Use large polyethylene (poly) gloves (available from VWR, catalog number 32915-268). They have shown no evidence of nitrate contamination and have no powder on the outside. Side note: previously we thought rinsed latex gloves were cleaner than nitrile, but this seems to be brand-specific. I would guess manufacturers use some cleaning agent to remove powder from these gloves so they are “powder free” but not necessarily surfactant free. VWR latex gloves from the chem stockroom are the next cleanest gloves available.

- Handle interior parts of the band saw (the blade) using polyethylene gloves

- Clean out ice powder from inside the band saw every 4-8 cores cut (may vary depending on core size). “Snow” that builds on the band saw casing will eventually become compacted, icy, and contact the band saw blade. If too much snow is around the edges it will put pressure on the blade and cause it to fall off the tires.

- If you have low concentration samples (e.g. WAIS divide) use angled cuts whenever possible. On average, you will get more water.

- To clean the blade before cutting each core, use frozen 18 MOhm water. There is a bin in the freezer labeled: FOR BLANK ICE ONLY. This was initially cleaned with Micro-90 + tap water, DI water, and 18 MOhm water (rinsed multiple times at each step). You can check cleanliness using the ion chromatograph in the Alexander lab.

Ice handling - The ice will be both dirty and clean for much of the time. Handle dirty portions of the ice with outer portions of your hand/glove and clean (cut) faces with interior fingertips. This way only clean fingertips will contact clean faces. If there is no way to grip the ice with your fingertips, the best way to pick up and move the ice is to ball both hands into fists. Have thumb from each hand facing each other: the thumbs tend to stick out slightly from the fist providing a shelf on which the ice can rest. The fingertips of your index fingers should be protected by your thumbs so they will stay clean. Gentle pressure from your closed hands + the shelf from your thumbs should provide enough stability to transport a 1 meter core.

Room for improvement:

- Adjustable height table/stand for the band saw itself. This would be especially helpful when doing cuts that have variable angles.

- Associated with differing table heights: a meter of ice is significantly longer than the bench of the band saw. As the balance of the ice changes it will tilt without applied force, and improperly applied force could cause the ice to break. Try to minimize differences in table height to make cutting straight lines easier.

- Glove washing procedure: I resorted to cleaning the gloves after I put them on, but it would be best to have a way to pre-clean gloves, then put them on without needing to touch the exteriors.

Safety

Risks associated with the band saw are related to the sharp cutting blade as well as the freezer you will be working in. You are expected to have read through this method and the manufacturers manual for the band saw.

The band saw can easily cause severe laceration or amputation. You must gloves to protect against the blade. Use a push stick to move the core through the blade as your fingers get within a few inches.

Flying objects such as ice debris or the blade itself are another risk. Wear eye protection. Always stand facing the teeth of the blade and the direction you are pushing the ice. Never stand with your body facing the side of the blade in case the blade brakes and exits the saw.

It is cold in the freezer. If you are cutting ice cores, you are likely going to be in there for a while. Protect yourself against hypothermia and frost bite with appropriate clothing.

Never cut alone. Make sure someone is in the lab. Tell them that you are preparing the use the band saw for cutting ice.

Exhaustive Protocol

FINAL PROCEDURE FOR CUTTING THE DD15 CORES FROM WAIS DIVIDE

- Adjust band saw table so it is at 26 degrees off horizontal

- Adjust table/cutting surface height for angled cut

- Open plastic sleeves that contain ice and slides ice gently onto the table

- Place clean 2-liter bottle to right of band saw (effectively upwind)

- Place hand rinsing beaker to right of clean bottle

- Put on polyethylene gloves (do NOT rinse --- you will only be touching dirty portions of ice with these gloves and as far as we know these globes are nitrate-free anyway)

- Start band saw and clean off the blade using blank ice. Make three thin cuts of the blank ice (blank ice should be 1-2 cm thick and 10+ cm long for this step)

- Brush away powder from blank ice

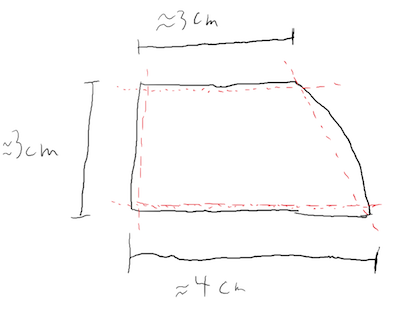

- Adjust guide rail to take off ice from edge-to-edge (see figure below). Slowly cut off curved edge from ice. Touch only dirty (uncut) faces of the ice with the unrinsed gloves.

- After cut, adjust height of the feeding table for so it matches the height of cutting table is horizontal (next step). Move ice from the receiving table to the feeding table (after brushing the feeding table as necessary).

- Brush away any pieces in the way and powder on the saw table (brush away from the ice core/in the same direction as air circulation). Adjust cutting table to be horizontal again.

- Remove polyethylene gloves. Put on a new pair of gloves and rinse fingers in the rinse beaker. From this point forward, interiors of fingers are kept clean. They can touch cleaned/cut faces of the ice core. Use backs and sides of fingers/hand to handle dirty faces of the ice.

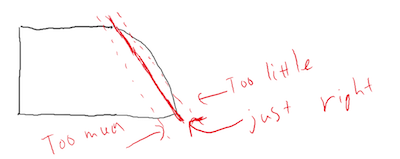

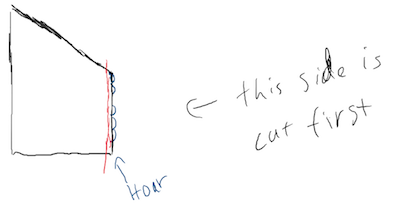

- Make cuts on base and top of your trapezoidal prism. If there is a face with a large amount of hoar creating an uneven surface, cut this face off first. Adjust guide rail as needed. Blade thickness is about 1 mm. The goal is to remove the thickness of the blade + 1 mm of ice + hoar (don’t count hoar in your thickness judgments).

- With the base and top cleaned, adjust guide rail to cut flat edge opposite the angled edge of the trapezoid. The sharp edge of the ice core is often uneven, so sometimes it is easier to guide the entire core slowly by hand rather than using the guide rail.

- Pick up the entire core with your (clean!) fingertips and cut into appropriately sized sections to fit into the plastic bottles or other container (usually 15-20). Cut off the ends of the core as well during this process.

BLADE REPLACEMENT

The keys here are recognizing when the blade needs replacement, making sure the teeth are aligned correctly, and tightening appropriately.

The blades usually seem worn out after about 1 core box has been cut. If you cannot seem to make the blade stay on for more than 1-2 cores, it is also time to replace the blade assuming there is not recognizable cause for blade jumps (like ice on the wheels). It seems like the blade might be stretched or bent slightly when it falls off, so multiple jumps mean you should consider replacing the blade regardless.

To replace the blade, start by turning the knob on the top of the band saw counterclockwise to loosen the blade and bring the two wheels closer together. Remove the old blade. Put the new blade on so it goes around both tires. Holding the blade to the top tire, tighten the blade by turning the knob on top of the band saw clockwise. Keep turning until the blade runs straight between the top and bottom wheels. I usually tighten 1 full turn beyond the point I notice the blade becoming straight. This seems to be a good tightness.

To adjust tracking, where the blade is on with respect to the tire, turn the knob on the back of the band saw. Turning counter clockwise moves the band saw toward the front of the saw, and clockwise does the opposite. The teeth of the blade should be hanging just off the tire.

OTHER BLADE ADJUSTMENT THOUGHTS

- The blade guides (polytetrafluorethylene) should be adjusted when the blade is replaced if necessary (it usually is). No more that 1 mm should be between the blades and the guides on either side. Don’t forget there are blade guides on both the top and bottom of the cutting table.

- The polyurethane tires do seem to wear out and ice will begin to build on them. This can be mitigated by the aforementioned cleaning process after every few cores. I am unsure why this occurs: either there is some ionic build up (oxides coming from the blade?) that allow ice to form more easily or the tires are wearing and increasing in surface area which might allow freezing. It may be possible to clean the tires with soapy water if oxides or other particulates from the blades are creating the ice nucleation sites.

- There are guide wheels that are intended to be placed close the blade to prevent the blade from moving/stretching too much toward the back of the band saw during operation. I have avoided using these at all because they seemed to be generating too much friction, creating heat that would cause melting rather than cutting. If the wheels have corrosion removed and are properly lubricated it may be possible to use the guide wheels appropriately.

EMAIL FROM GEOFF HARGREAVES AT NICL

Parts that might need replacing

- Urethane tires - 1760, 3/4" width x 11" Dia. Urathane Band Saw Tire - 2 Pack, from http://www.ptreeusa.com/band saw_tires.htm. The only things we have changed are the bearings in the top wheel idler wheel bearings for INCA saw rebuilds

- HK1210_CAGED NEEDLE BEARING KAMAN Industrial Technologies $4.53; and the back bearings on the guides (use cheap roller skate bearings get the number off the side of the bearing)

- I have replaced my guides with ceramic from here: http://spaceageceramics.com/products/inca-340-guide-blocks/

- HOWEVER we often over tighten the blades a bit and don't really adjust the side guides in very tight at all (~2mm space?), the back bearing has to be about right, or the blade will walk back on the wheels when the blade gets dull.

Tips from Geoff

Things that make the saw blade jump are, ice on the tires, bad tires, worn bearings on either or both the upper idler wheel or on the motor. I have had one motor go bad in 20+ years. We have changed the upper needle bearings .......once? maybe twice. Not because they were worn, but just a precaution. they are press in.

If you replace the upper bearings, BE CAREFUL, COUNT THE SPACER/WASHERS IN FRONT AND BACK OF THE WHEEL when you take it off. These spacers set the alignment of the upper wheel to the lower wheel. Grease the upper bearings with a lowtemp lithium grease (lubriplate is what we have). The guide back bearings we change all the time., usually not the cause of thrown blades. When you change to the urethane tires you will alleviate the iceing problem, snow and ice just doesn't seem to stick to the tires like it does to the rubber tires.

Also at the end of a cutting session, you should release the tension on the blade (put a sign on the saw telling you to re-tension) it will help the life of the tires. now ask if we do that...well, no, and the tires seem to survive.